Trail Grabbers – Best Alternative to Standard Studs

Improve control on icy surfaces and reduce damage to trails and road

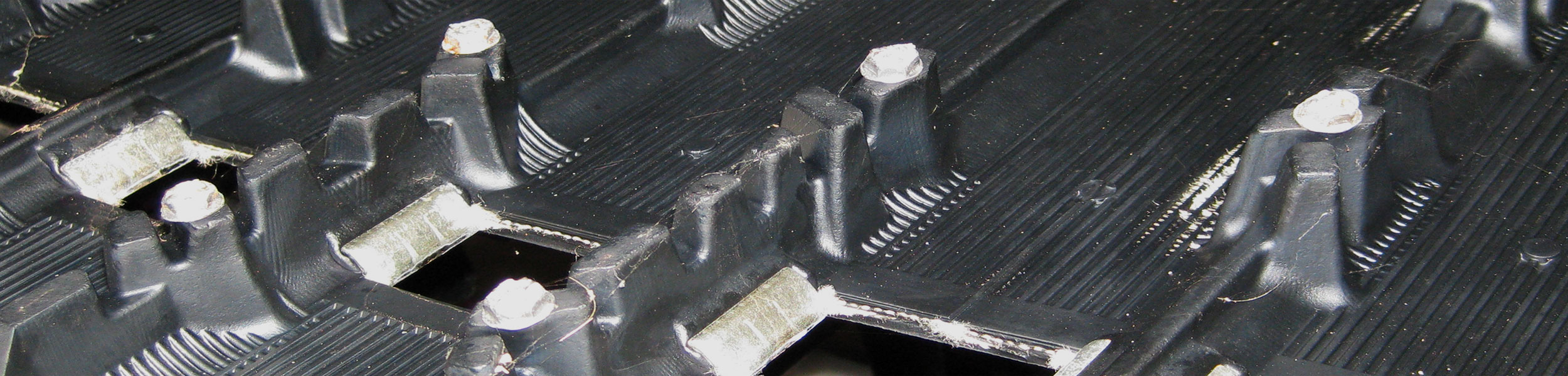

Trail Grabbers offer an alternative to traditional snowmobile studs, giving you the traction you need while minimizing damage to trails and pavement, and your track!

Rather than the single carbide tipped design of most studs, Trail Grabbers feature a “dome” of carbide chips brazed to the head of a stainless steel screw. When touring, Trail Grabbers handle all the safety “stuff” that traditional studs do – icy hills, icy corners, lake crossings and, of course, stopping. In short, they keep the track where it is supposed to be. They do not penetrate, or damage, like studs. They do a lot of scratching instead.

Trail Grabber Benefits

- Improves control on icy surfaces

- Longer lasting than standard studs

- Reduces damage to pavement

- Minimal damage to track

- 1/10th the weight of traditionall studs

Low profile and screw-in design offers minimal track damage and maximum traction

Why Choose Trail Grabbers over Standard Studs?

Trail Grabber Design Advantage

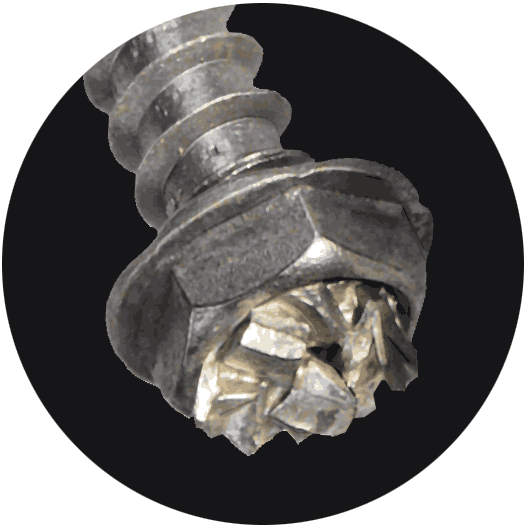

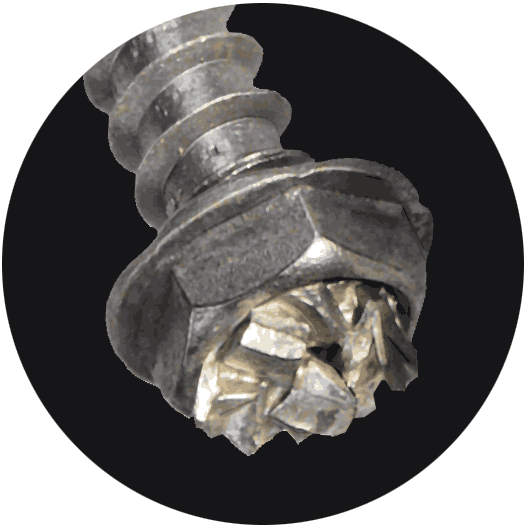

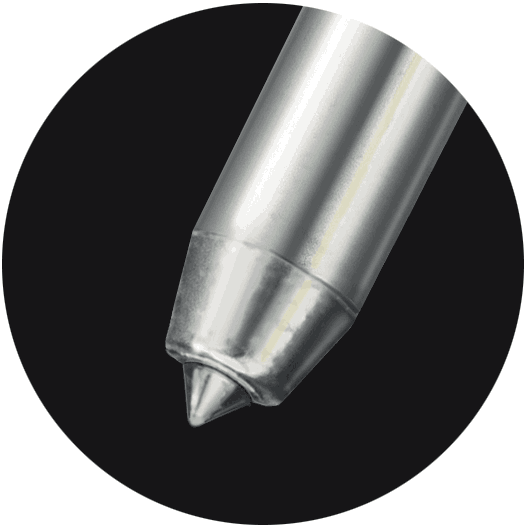

The head of the Trail Grabber is domed with carbide chips on a 5/16″ hex head stainless steel screw so it will scratch the surface rather than penetrate like regular studs. And the 1/4″ stick-out above the lugs will allow the track to follow the skis. Multiple layers of carbide chips prolong the life and function of Trail Grabbers. Combined with Ski Savers, Trail Grabbers will keep you straight and in control in any condition.

Using carbide chips domed on top of the screw head provides two more advantages. First, because of their unique design Trail Grabbers put far more carbide on the ground by weight than regular studs. Second, you have to wear through all the carbide chips before getting to steel screw to which the carbide chips are silver brazed. This eliminates the typical stud problem of the steel wearing away until the carbide falls out.

Trail Grabbers last much longer than regular studs. As the carbide chips wear, new points and edges are exposed, extending the life and usefulness of the Trail Grabber.

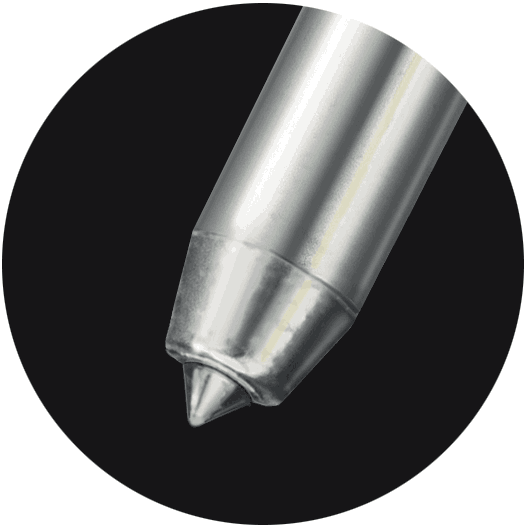

Most standard studs (push through or screw in) have a single carbide tip. When the carbide wears down the steel wears away, and the carbide eventually falls out.

Trail Grabbers last much longer than regular studs. As the carbide chips wear, new points and edges are exposed, extending the life and usefulness of the Trail Grabbers.

Most standard studs (push through or screw in) have a single carbide tip. When the carbide wears down the steel wears away, and the carbide eventually falls out.

Trail Grabber Riding Characteristics

Trail Grabbers are not overpowering. A 6″ carbide wear rod will turn a sled with 240 Trail Grabbers. There is no stud wobble. The track is not nailed to the ground! Regular studs dictate when and how your sled turns. Trail Grabbers follow your skis and respond to you.Recommended Number of Trail Grabbers

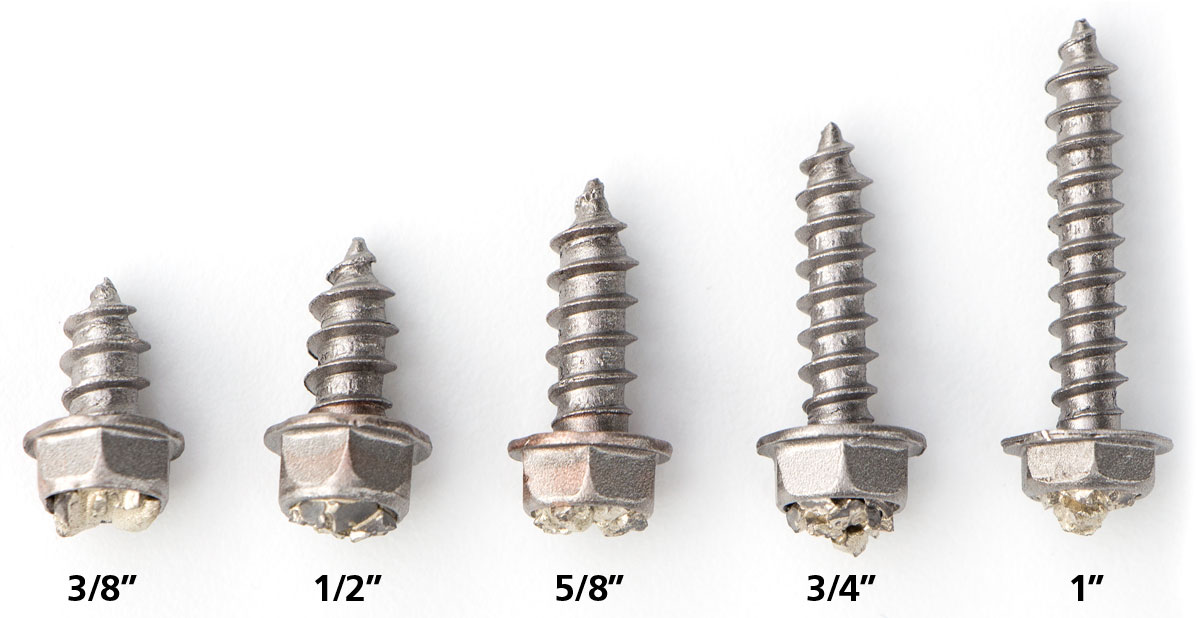

Trail Grabber Screw Sizes

Which screw size should you use?

3/8″ use in lugs .725″ to .750″

1/2″ use in lugs .85″

5/8″ use in lugs .88″ to 1.00″

3/4″ use in lugs 1.25″ to 1.375″

1″ use in lugs 1.6″ and up

Standard Length Tracks

| Engine Size | # Grabbers Per Row | Total # of Grabbers |

|---|---|---|

| Any | 2 | 0 to 96 |

| 340-440cc | 2 | 96 to 120 |

| 480-500cc | 3 | 144 |

| 580-600 | 4 | 162 to 192 |

| 650 - 700 cc | 5 | 216 to 240 |

| 750 - 800cc | 6 | 264 to 288 |

Long Length Tracks

| Track Length | Rows of lugs |

|---|---|

| 133.5 in | 53 |

| 136 in | 54 |

| 139 in | 55 |

| 141 in | 56 |

| 154 in | 61 |

| 156 in | 62 |

Recommendation for Tracks over 600 cc:

Because more lugs are on the ground and this type of sled is usually not driven aggressively, you may use fewer per row. That is, if the cc chart would normally take you over 4 per row. If you ride 2-up or pull a cargo sled, we suggest you stay with the regular recommendation of Trail Grabbers per row per cc (as shown above)

Pricing: | Trail Grabbers (each) – all sizes – $1.00 (US/CA)

Pricing:

Trail Grabbers (each) – all sizes – $1.00 (US/CA)